How furniture is created From the idea to the finished sofa

Comfort, and quality are our passion. More than 70 years, the W.SCHILLIG family has handcrafted the finest leather upholstery produced in Germany and around the world. We engineer our seating to ensure consistent, long-lasting comfort. Our designers work hand in hand with our frame engineers and upholstery specialists to ensure comfort meets fashion. We hand select the finest leathers and raw materials from all over the world. Our goal is to provide the best quality furniture at the best value.

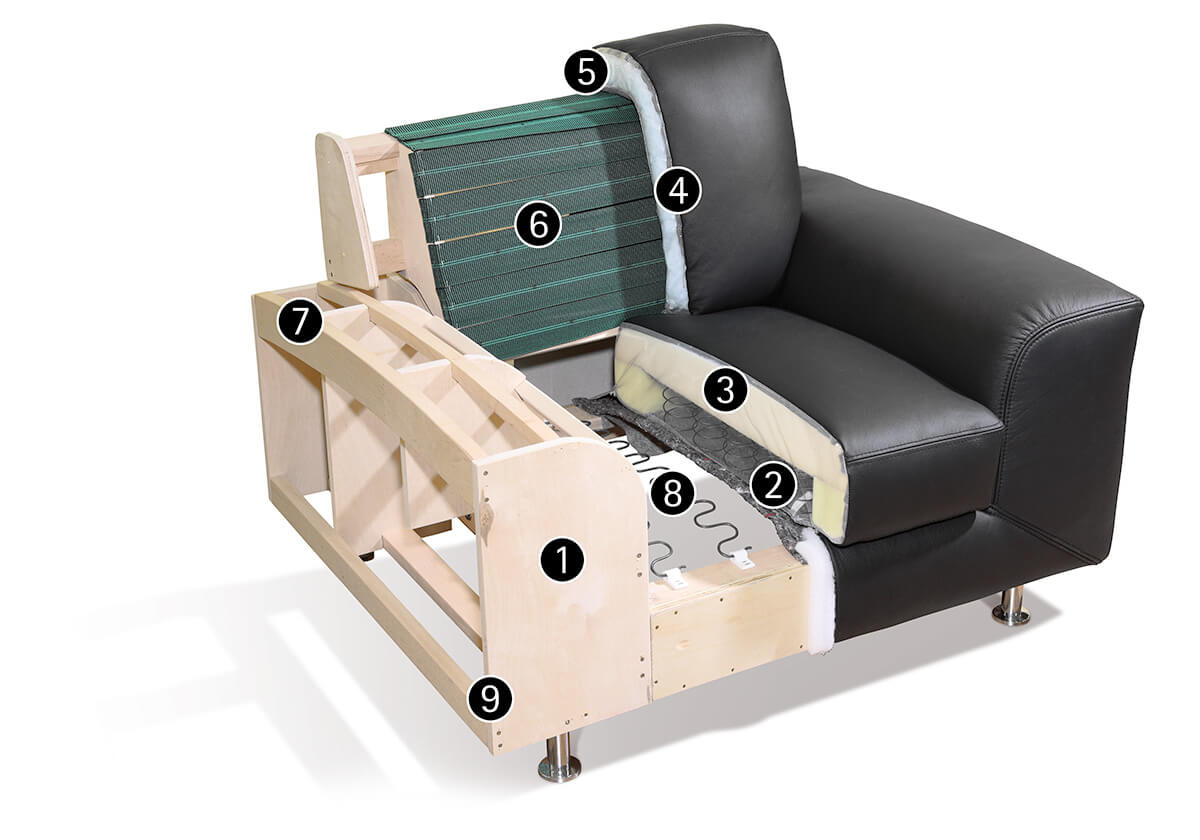

Furniture quality: a look inside

- Hardwood Frame W.SCHILLIG frames are constructed of kiln dried hardwood and top-grade ³/4" plywood, double doweled, glued, and stapled joints dramatically increase stability and durability.

- Spring Coils W.SCHILLIG seats are engineered with steel coil springs to create consistent, long lasting comfort. And, for additional comfort, we intertwine the coils in high density foam.

- Cushioning High-density cushion foam.

- Dacron cushioning This high-quality synthetic support provides for cosy, soft seating comfort and a modern, casual look (is attached to or glued on the quilted back cushion).

- High quality leather or fabric W.SCHILLIG selects top grain cow hide leather. Chosen from the top 4% of all hides, our fine leathers offer a luxurious seating surface. We work with the top mills to provide great fabrics.

- Elastic webbing in the backrest acts as an additional suspension for soft, long-lasting flexible support of the body.

- Plywood side frame All cuts for stress areas (e.g. side parts) are made of plywood and offer the same stability as massive hardwood.

- No-sag suspension Incorporating nosag-suspension is the best way to provide permanent, ergonomic support.

- Hand-crafted Connections side pieces and frame are dowelled, stapled woods base-stabilized: manufacturing with traditional handicraft in time-tested durability.

1. Cutting

Here the experience of our employees is in great demand! Up to seven hides are needed for a normal-sized leather sofa. These are checked by the cutters for unsightly flaws such as scars, brand marks etc. Then, every individual piece of the sofa is marked on the hide and the corresponding pieces cut by hand according to template. After a final inspection, the cut pieces are sent to the sewing department. Single-coloured fabrics or fabrics with very small patterns, however, can be prepared on the fabric cutter. A vacuum sucks the fabric down onto the cutting table. The single pieces are then automatically cut according to a pre-made template.

2. Fleece

When cutting fleece, many layers of fleece are placed on top of each other on a long table, covered with plastic foil and a vacuum is applied, pressing all layers together. This way, several layers of fleece can be marked and cut at the same time. The furniture becomes soft and cuddly by using fleece.

3. Leather edging

Thick leather must be bevelled in the areas where the seams will be, otherwise it will not be possible to sew the seams with a sewing machine.

4. Sewing department

The first step is to sew together the fleece and the leather/fabric pieces that are to be particularly soft (e.g. outer edging, seat and back cushions etc.). Hereafter, single pieces are gathered on a special machine. This is the terminology for »deliberately adding folds« to create a casual look to the furniture. Only then are the still separate pieces placed on the sewing assembly line. Our qualified specialists sew together approx. 220 parts per suite to create a cover for the furniture. One employee sews the complete suite so as to maintain a uniform look. Later on, the contrast stitch is applied with the double-needle sewing machine. Every cover is carefully checked for flaws in a final inspection.

Exciting insights behind the scenes

5. Filling cushions

Strength is needed here! The upholstery covers coming from the sewing department are filled by hand with large seat and back cushions. For safety measures and for better durability, the cushions are glued on the bottom.

6. Pre-upholstery

Massive hardwood is the ideal material for especially durable and long-lasting furniture frames and thus is used for the frame and supporting connecting parts. The bonding and the dowelling as well as assembling the pieces are done by hand. The seat is equipped with nosag-springs. The fastenings for the nosag-springs are sturdily attached by hand to the frame with pre-determined spacing. Strong elastic-webbing is used in the back. Finally, the frame is encased with foam and fleece.

7. Upholstery department

The upholstery department is the heart of the production (comparable to the final assembly for automobiles)! Only the highest quality materials are used and the experience of the employees is of utmost importance! The filled cushions from point 5) are draped onto the upholstered frame from point 6) and optional functional hinges attached. The cover is tightened and nailed onto the frame. Finally, the draped back cover is aligned. With the help of spanning strips, the cover can then be fastened to the frame. It is especially important to neatly upholster the edges, the front side and the facing. Plastic feet are attached for safe and careful delivery.

Exciting insights behind the scenes

8. Quality control

Every piece of furniture undergoes thorough inspection. At the final quality control, the craftsmanship, seating comfort and all existing functions are checked. The flawless quality is then documented with digital photographs, to rule out later complaints. Only after successfully passing all tests may the furniture be packed and shipped. For each order, product information is also gathered for delivery.

9. Delivery

An affiliated logistics company provides for safe and careful transport to the customer.